|

Product Links

|

|

Inside SRI

|

| SRI-Newsletter |

|

Subscribe to our newsletter to receive monthly specials, manufacturer's feature, and electronics news via email. |

|

|

|

See Our latest release of SRI-Newsletter here

|

|

View Our List of Archived Newsletter Articles

|

|

SRI Links

|

|

Visit our Sister Site,

Distributor of

Industrial Products

| |

|

Web Search ..

Powered by;

|

|

|

|

ESD: Is your company equipped?

| Many different industries have been battling static electricity and its companion electrostatic discharge (ESD) for well over a century. Certainly ESD is a major issue for the electronics industry, which has taken many steps to curtail the effects of ESD. Much of the problem stems from suppliers and consumers not understanding how and why ESD can cause so many problems. Being aware of the effects of ESD and how to manage them can potentially save your company millions of dollars. This article provides some facts about ESD and a few methods and products that are available to reduce the threat.

Electrostatic Discharge (ESD) is the rapid discharge of static electricity from one conductor to another of different potential. Triboelectric charge generation is a common cause of ESD. This occurs when two non-conductive objects come into contact and are separated. Electrons are transferred from one surface to the other making one surface positive and one negative. Walking across carpet is a common example of this. The amount of static buildup depends on the materials involved (see the Triboelectric Series Table).

During a normal workday the human body can store between 1000V- 2500V and is capable of storing over 20,000V. Workers in many cases are unaware of this because human touch is only sensitive on ESD levels that exceed 3000V while electronics can be sensitive to as little as 30V. Once generated, these static charges can remain on the surface for hours, even days. Because so many sources of static electricity can be found in the workplace, removing it completely is doubtful, but many steps can be taken to control the threat.

One of the simplest methods to preventing ESD is to wear a grounded wrist strap. The wrist strap cord has a current-limiting resistor that will slowly dissipate the electrical charge through a grounded wire. It is commonly used with a dissipative tablemat and/or floor mat to prevent voltage from building up while handling components. Many other products are also available for ESD prevention like gloves, lotions, smocks, ionizers, floor mats, workstations, foot and wrist straps, vacuums, sprays, tape, trash receptacles and liners, chair covers, tools, and much more. Not all static materials fall under the term "anti-static." Many of the products used for this purpose fall into two general classifications: anti-static and electrically conductive. The ESD Association (see www.esd.org) has two categories of electrically conductive materials: Conductive materials have a surface resistivity of <1 x 105 ohms per square. Static dissipative materials have a surface resistivity between 1 x 105 and 1 x 1012 ohms per square. Electrically conductive ("conductive" and "static dissipative") materials conduct static charges and spread the charge over the surface of the material in order to reduce the amount of charge at any given point. Anti-static materials function to reduce tribogeneration even when rubbed against insulative materials.

|

Triboelectric Series Table

|

Positive (+)

|

|

Air

|

|

Human

hands

|

|

Asbestos

|

|

Rabbit's fur

|

|

Glass

|

|

Human

hair

|

|

Mica

|

|

Nylon

|

|

Wool

|

|

Lead

|

|

Cat's fur

|

|

Silk

|

|

Aluminum

|

|

Paper

|

|

Cotton

|

|

Steel

|

|

Wood

|

|

Lucite®

|

|

Sealing

wax

|

|

Amber

|

|

Polystyrene

|

|

Rubber

balloon

|

|

Hard

rubber

|

|

Nickel,

copper

|

|

Brass,

silver

|

|

Gold,

platinum

|

|

Sulfur

|

|

Acetate,

rayon

|

|

Polyester

|

|

Celluloid

|

|

Polyurethane

|

|

Polyethylene

|

|

Polypropylene

|

|

Vinyl

|

|

Silicon

|

|

Teflon®

nonstick coating

|

|

Plastic

wrap

|

|

Negative (-)

|

|

|

Many electronic devices are ESD sensitive. Be sure to take the following precautions when handling an electronic device:

Always wear an anti-static wrist strap

Handle circuit boards by the edge to prevent direct contact to leads and soldering

Never attempt installation on a carpeted floor

Never wear leather shoes (rubber soles are recommended)

Never attempt installation in an overly dry environment

Never wear silk or polyester clothing during an installation

Always remove all jewelry (i.e., rings, bracelets, watches, etc.)

Always transport and store electronic devices in static-safe containers (tubes, bags, boxes)

ark items with warning labels (see above example)

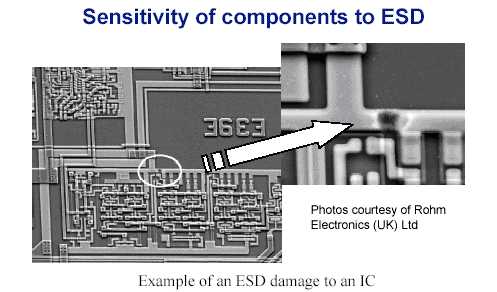

Below are some examples of the damage that ESD can do to components.

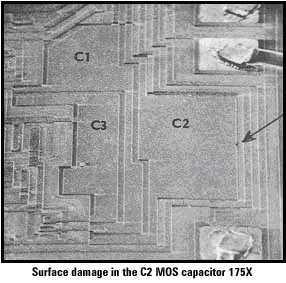

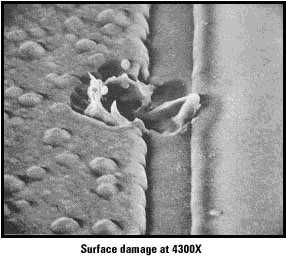

Here are two images showing ESD damage to a C2 MOS capacitor. What appears to be a slight pinhole on the top image shows to be substantial damage to the trace when examined at 4300X.

For more information on preventing ESD, contact a local electronics distributor or ESD equipment manufacturer.

Generally damage is classified as either a catastrophic failure or a latent defect.

Catastrophic Failure

Once an electronic device is exposed to an ESD event, the devices circuitry (like in the photos above) may be permanently damaged causing the device to fail. Usually this can be detected using a basic performance test.

Latent Defect

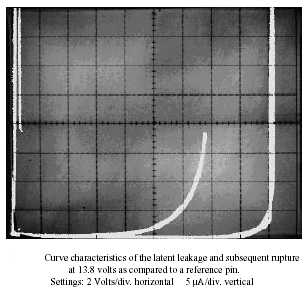

A device that is exposed to an ESD event may be partially degraded, yet continue to perform its intended function. ESD latent damage may be detectable by its electrical signature but its lifetime behavior is not predictable. One example can be seen below. Latent damage can result in permanent failure under some stress conditions making the device unreliable. Device outputs with latent damage can fail if current is passed through, but is less likely to happen under nominal electrical fields. This depends on the location of the damage. Damaged junctions are more likely to fail than input resisters.

Much more could be discussed about the subject of ESD. Future articles will include the Human Body Model (HBM) and the Charged Device Model (CDM). Proper ESD workstations and to a greater extent, clean rooms will also be covered.

|

**Specifications subject to changes**

|

|

|

|

Product Spotlight

|

|

|

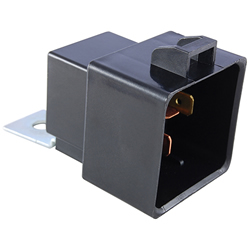

SPST-NO 50A 24VDC Shrouded .250 Inch QC Terminal w/Mounting Flange, Weatherproof

$4.69

MORE INFO

More NTE

|

|

|

Time Delay Relay - 10AMP - A/C 120V - 0.1 to 10 sec Delays

$103.44

MORE INFO

More NTE

|

|

Sponsored Ads

|

|