|

Product Links

|

|

Inside SRI

|

| SRI-Newsletter |

|

Subscribe to our newsletter to receive monthly specials, manufacturer's feature, and electronics news via email. |

|

|

|

See Our latest release of SRI-Newsletter here

|

|

View Our List of Archived Newsletter Articles

|

|

SRI Links

|

|

Visit our Sister Site,

Distributor of

Industrial Products

| |

|

Web Search ..

Powered by;

|

|

|

|

|

|

|

Although the concept of laser solder has been around since the late 1970’s, it has not been a widely used solder method until now. To comply with RoHS legislation in Europe last year, manufacturers now use materials that require higher reflow temperatures for soldering, which can result in damage to surrounding components unless precautions are taken. With the advent of newer reduced cost, high-power diode lasers, selective soldering with laser now is gaining wider acceptance for production of printed circuit board assemblies and miniature interconnects. Some parts are too small or too light to be soldered using contact heating. In both cases, lasers offer opportunities in non-contact selective soldering that succeed where other methods fail. Although the concept of laser solder has been around since the late 1970’s, it has not been a widely used solder method until now. To comply with RoHS legislation in Europe last year, manufacturers now use materials that require higher reflow temperatures for soldering, which can result in damage to surrounding components unless precautions are taken. With the advent of newer reduced cost, high-power diode lasers, selective soldering with laser now is gaining wider acceptance for production of printed circuit board assemblies and miniature interconnects. Some parts are too small or too light to be soldered using contact heating. In both cases, lasers offer opportunities in non-contact selective soldering that succeed where other methods fail.

Gary Goldberg, in SMT Magazine, recalls that many articles have been written about the corrosive nature of lead-free alloys, how increased weight will wear internal parts in both existing and newer machine technologies, as well as the effectiveness of higher temperatures on PCBs and certain components. “While many strides have been made to address each of these issues, non-contact laser-soldering systems do not deal with any of these matters. Instead, this technology works successfully around them, making non-contact laser soldering a viable option in today’s manufacturing environment.” Gary Goldberg, in SMT Magazine, recalls that many articles have been written about the corrosive nature of lead-free alloys, how increased weight will wear internal parts in both existing and newer machine technologies, as well as the effectiveness of higher temperatures on PCBs and certain components. “While many strides have been made to address each of these issues, non-contact laser-soldering systems do not deal with any of these matters. Instead, this technology works successfully around them, making non-contact laser soldering a viable option in today’s manufacturing environment.”

Laser soldering is used in many applications where:

- Heat sensitive components are involved, as thanks to very short and precise heat application, laser can be used to solder in components containing plastic housings, LCD displays, micro sensors and other heat sensitive devices.

- Selective components are added to a board with preexisting components that can be damaged or altered if the entire board is reflowed.

- Components on the board have different reflow requirements

- High joint quality and repeatability is required

Laser soldering is widely used in applications where localized heat and non-contact soldering is desirable. Newer systems have adjustable beam size without changing nozzles, CAD/CAM support, automatic solder feeding, adjustments for preheating and cooling for varied solder types, and dynamic motion control. This allows for a supreme amount of flexibility in a wide variety of applications. The solder alloy can be delivered in a solder wire, solder paste or deposited prior to placement of components. Each method has its own advantages and downsides and used with accordance to specific project requirements. Laser soldering is widely used in applications where localized heat and non-contact soldering is desirable. Newer systems have adjustable beam size without changing nozzles, CAD/CAM support, automatic solder feeding, adjustments for preheating and cooling for varied solder types, and dynamic motion control. This allows for a supreme amount of flexibility in a wide variety of applications. The solder alloy can be delivered in a solder wire, solder paste or deposited prior to placement of components. Each method has its own advantages and downsides and used with accordance to specific project requirements.

Laser systems are cost-effective and require a minimal amount of maintenance. They require no nitrogen and use both flux-core and no-clean soldering wires for the process. In a high output environment, a few calibrations may be required and the lens should be kept clean. Laser systems are cost-effective and require a minimal amount of maintenance. They require no nitrogen and use both flux-core and no-clean soldering wires for the process. In a high output environment, a few calibrations may be required and the lens should be kept clean.

In the long run, the soldering process selected is going to be a result of the mix of components to be soldered. Laser soldering should not be considered mutually exclusive, but rather compliment other methods.

Sources:

http://www.leisterlaser.com/overview_s.asp

http://www.emasiamag.com/article-3009-lasersolderreflowapplications-Asia.html

http://smt.pennnet.com/....Soft-Cost-Considerations/

http://www.ma-info.de/html/laser_soldering.html

|

**Specifications subject to changes**

|

|

|

|

Product Spotlight

|

|

|

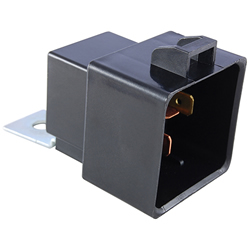

SPST-NO 50A 24VDC Shrouded .250 Inch QC Terminal w/Mounting Flange, Weatherproof

$4.69

MORE INFO

More NTE

|

|

Sponsored Ads

|

|